How to build a screen with RGB PC fans

1. Introductions

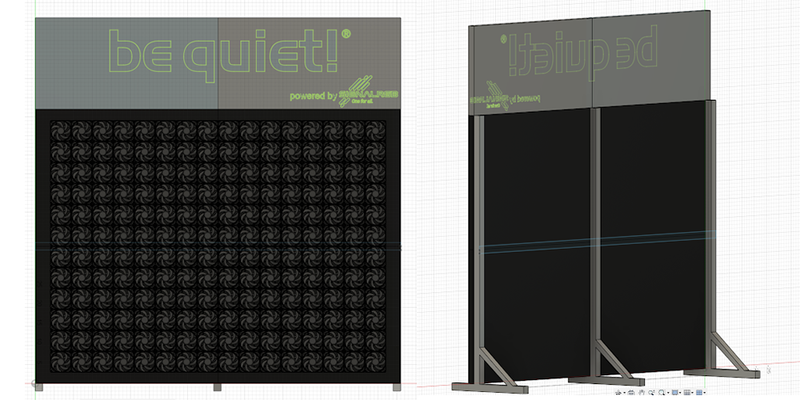

This blog will document how we at SignalRGB built a wall of ARGB fans for Bequiet!. This will be a guide for you to base your own projects off of and may be used as inspiration and as well as give insight to some problems you may encounter in your own designs. There are details on the products used and links at the end of the blog for some of the specialty materials used.

2. Preparations

Before you begin your project, plan out what you hope to accomplish. This will help you come up with a solid idea for materials and will let you mitigate problems later on. We like to start with a rough 3d render of the project to ensure the design is what we want it to be. Now is an important time to really put thought into how you will overcome obstacles like material choices and layout, the more detail the better. This will come over many design iterations but it is good to solidify the plans now while designing it in 3d.

3. Materials Note, there are exact numbers of parts used in this project but you should always buy extra beforehand in case you lose some bolts or damage them. Exactly how many were ordered with extras included will be at the bottom with the parts lists.

3.1 Frame

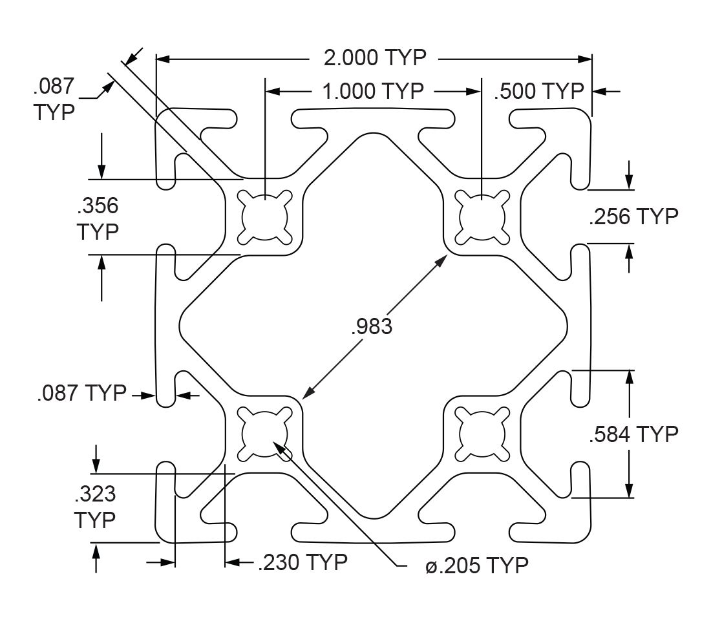

For this project we used 2” extruded aluminum extrusions for the frame. The wall is an 8’x8’ square with a 6’x8’ section for the fans and a 2’x8’ section for the signage on top connected by a frame. The frame is 3x identical pieces of 72”x2”x2” aluminum extrusion with M6 tapped ends. The feet are made from 36”x2”x2” aluminum extrusion. The uprights are supported with 12” 45 degree 1020 supports. There are 2” adjustable feet with some bolts and washers that attach to the feet. The uprights attach to the feet with M6x65mm socket head screws. 3.2 Wall

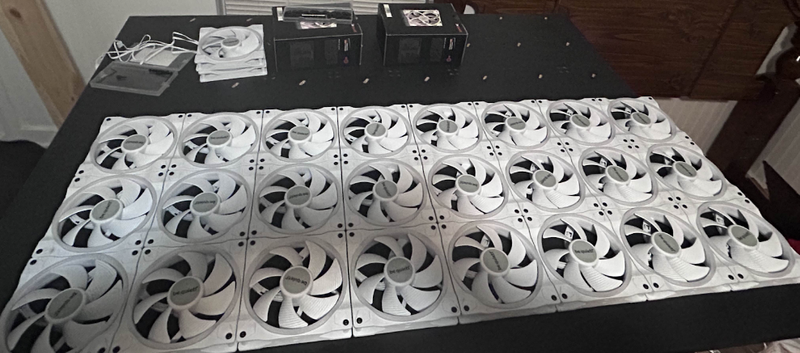

The wall main section is made with 2x 4’x 8’ x 3/4” sanded pieces of heavy duty plywood. Since the frame is not connected to one another this piece must be sturdy to support the weight of the project. The wall is connected to the frame using 24x 90 degree slotted corner brackets with 24x M6x10mm socket head screws , and 24x M6x14mm socket head screws. The bracket attached to the frame with the 10mm screws using a M6 T-nut with centered thread you will need roughly 50x of these M6 T-nuts for this project. The wall will use 24x M6 x 1/2” brass threaded inserts to attach the panels to the frame. The wall uses 192x 140mm fans which are attached to the wall using 768x M4x16mm button head screws with 768x 1/2” OD x 3/16” ID x 1/16” thick rubber washers. These screws need 768x M4x10mm hex socket threaded inserts to attach to the wall.

3.3 Signage

The Signage on top uses some of the 3/4" plywood from the main wall but also uses 2’ x 8’ of 1/4" thick plywood along with 20’ of 1” x 1.75” wood strips. The electronics of the sign will be detailed in their own section.

4. Assembly

4.1. Start by building the frame. Take the 36” foot pieces and mark them at the 18” spot, choose one side and mark 1/2" in the middle of the slots from the middle and again 1” from there to mark where to drill the holes needed for the uprights. Drill the holes using a drill press to ensure they are square using a 6mm drill bit. You will need to countersink the bolt by drilling out the rails using a 10mm drill bit to ensure the bolt can fit snugly against the feet. Next on the same side you countersunk the bolt head 1.5” from each end in the center of the foot, drill a 12mm sized hole for the leveling feet and attach the feet. Follow assembly instructions below to finish building the feet.

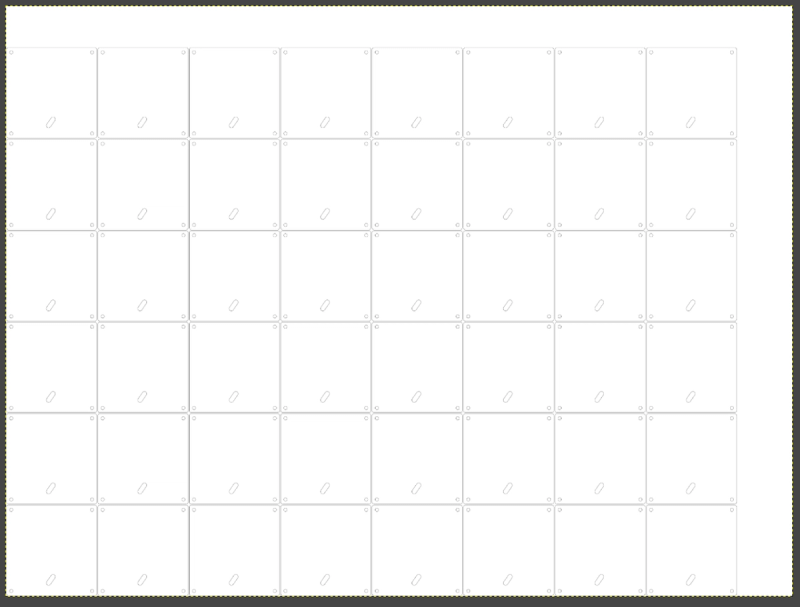

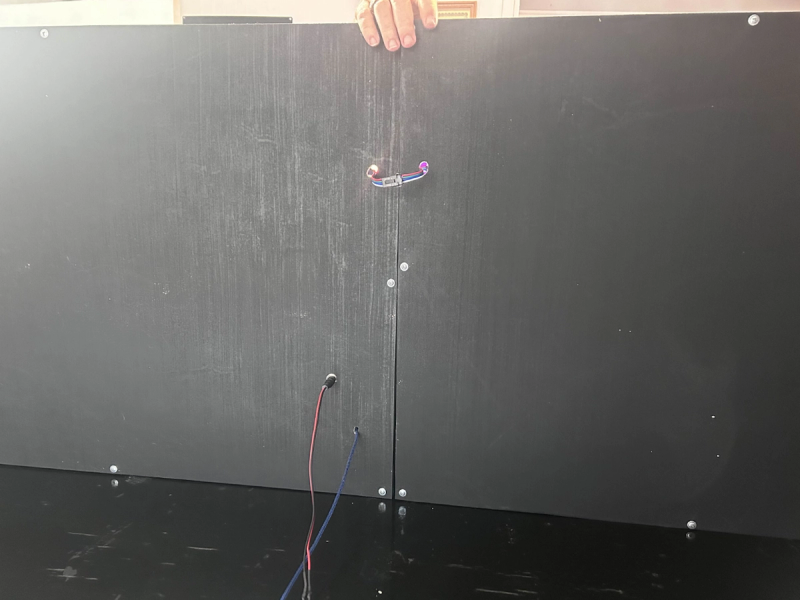

4.2. The wall panels are next to be built. It is important that while cutting the wall panels on the CNC machine you take great care to keep the same panels together as their slight natural warps later on will make the wall harder to assemble. When we assembled the wall we had a local CNC machine shop help us with the hole placement. The fans all had a consistent 1/16” gap between the fans and a 1/16” spacing to the outer edges (will make it 1/8" gap between the 4 panels but the gap is necessary due to structural rigidity needs), and we had small .3x.75” cable channels cut behind the fans offset behind the hub so the wires could not be seen from the front but also forced every fan into the same rotation (this is incredibly critical). (See CAD files below for layouts shown here) On the back side we hand drilled six 1/2" deep by .375” holes to put the threaded inserts to attach to the frame. Once all the holes are drilled, paint the panel with 2-3 coats of paint to ensure a smooth even coating. We recommend using only paint rollers for painting.

Next we recommend using saw horses to hold the panels while you add the fans. Start by installing all of the M4x10mm threaded inserts, to install the fans start by pushing the wires through the cutout and placing the neoprene washers over the inserts. Next put the M4x35mm screws through the fans and align and screw on the fan ensuring the washers are properly on the screws. Once all 4 wall panels are assembled you can install the M6 threaded inserts on the back to attach to the wall, adding some epoxy to the inserts to ensure they do not come loose.

Once the panels are assembled you can attach them to the uprights by following the instructions in 5.2 and 5.3 and once assembled can continue working on the project by next making the kick boards. The kick boards are NOT load bearing and are not meant to be stood on. Take the remaining 3/4" plywood piece and cut two 17.25” x 4’ panels and drill 1.5” x 1.5” in from each edge a 7mm hole and countersink it. Next, paint the panel, once dry add a 6mmx25mm flat head bolt to each hole and loosely attach a T-nut to each. Follow instructions in 5.5 to install the kick plates.

Take this time to install the Power supplies at this time, We recommend 8x 650W ATX PSUs with 2x PSUs per panel. This many PSUs are needed due to the sheer amperage being drawn on the 5V rails. On the upper part of the panels centered between 4 fans take a 2” strip of heavy duty velcro and screw it to the wall using the #8 wood screws using at least 3 per strip for support. The strap should be enough to wrap around the PSU with at least 6” of overlapping velcro. We would also now label the panels so the wall can be rebuilt identically every time. Do not mount the PSUs in the middle as the RGB controllers must go there instead. Add a 4” x 2” strip of velcro below the PSU in the middle and attach with 2x #8 wood screws for the controller.

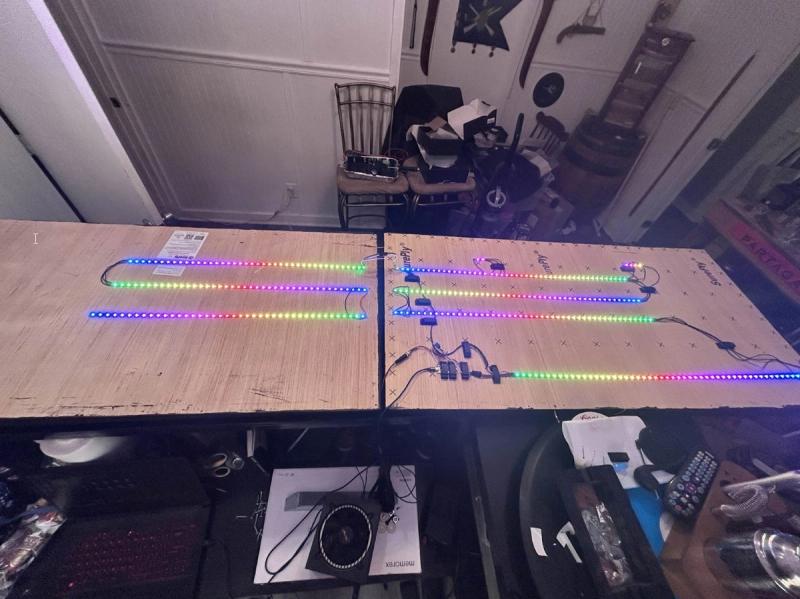

Next we must build the signage. The Sign is 2’ x 4’ x 2.75” and is one of the most complicated parts of the wall itself. The letters for the sign are made from white opaque acrylic that sits on a lip on the front of the sign so that it is flush. Paint the wood for the signage and let dry including the front, back, and the 1” x 1.75” side pieces. The letters are epoxied in place to ensure they do not fall out. The Lip is 1/8" wide and 1/4" deep all around the letter with any middle sections like the middle of an O using a piece of wood that also has a lip on the same dimensions to be consistent. Once the epoxy has dried use liquid nails and brad nails to attach the sides of the sign to the front ensuring the total depth of the sign without the back is 2.5” (.75” plywood with 1.75” wood siding)

The Internals of the sign use a teensy with a level shifter. Where 12V is supplied to the WS2815 ARGB 12V strips but also is shared with the controller/level shifter which needs 5V. This is done by splicing the 12V from the controller into the level shifter which is also shared to the ARGB strip. The USB cable should also be soldered onto the teensy so that it is not able to become unplugged once sealed in the sign, this is easily done by a small bit of solder on the USB ports and cables exposed outer grounding. You will need to flash the controller before completing the sign as well. Add a 12V barrel plug to the back of the sign to pass through 12V to the sign and connect it to the level shifter and strip. The ARGB strips should be laid out behind your sign lettering with at least 3 strips per letter and it may be necessary to add a couple of LEDs for some parts of letters like the dots of i’s. Both sides of the sign can be one strip; just use a connector piece (like the ones included on the second roll) to make a quick disconnect between the signs. You will need to manually solder jumper wires to the strips to have them be continuous.

Once the main wall is built you will need to modify the PSU cables by cutting and soldering the Molex cables included with the PSU to make custom 5V XT60 connectors. The fan speed controllers also use molex so be aware of the PSU model you buy to ensure it comes with enough molex cables. We recommend the BeQuiet 650W Pure Power 12M due to its modular nature with the required cables needed. You will also need 24 pin jumpers to ensure the PSUs can power on.

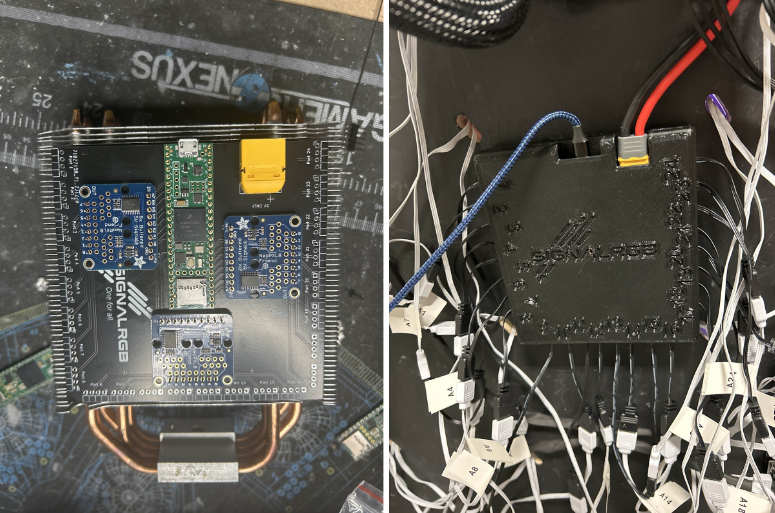

The controllers for the wall are made using a single teensy 4.1 microcontroller, three adafruit neopxl8 friend level shifters, one custom PCB, One XT60 connector, and twenty four 3 pin ARGB cables. First solder all the components onto the PCB taking care to ensure the pinout on the cables are correct. Hot glue the wires for strain relief and let cool. Flash the firmware to the teensy by clicky verify in the arduino app and once it compiles it will launch a teensy flashing software. Connect the teensy with a USB cable and press the button on the teensy. Once all the controllers are flashed and ready you will need to prep the 3D printed cases by removing the excess plastic and on the top part using a soldering iron to install the heat set threaded inserts. Place the controller in the case and carefully align all of the wires into the holes and clamp the case halves together and screw together with M3 screws. Attach a 4” x 2” strip of adhesive velcro and add a couple drops of super glue and let dry. Attach to the wall on the previously installed velcro strip, and wire the fans accordingly.

5. Assembly instructions once built for tradeshows.

Assembly Instructions

Note: This wall is to be built using hand tools only and under no circumstances should a drill be used even if it has a clutch. Take extreme care to avoid stripping the inserts, always start with reversing the screw until you are confident the bolt is going in correctly without stripping, the main inserts are brass due to their size and are easily stripped. Hand tools are included to build the wall.

5.1. Start by building the frame, the frame consists of one upright piece (6’ aluminum extrusion) and one foot piece connected with 4x 6x65mm bolts attacheched though the bottom into the threaded end of the upright. Before connecting the upright slide on the 45 degree support to the feet and then slide on the upright and bolt the upright to the foot and then tighten the 45 degree support ensuring it is flush on both ends. Do this three times to build all frame pieces.

5.2. Next take 2 assembled frame pieces and set them where you wish to build the wall. Take note the upright is not in the center of the foot, face the longer end to the front of where the wall will face. Determine which of the frame pieces will be the middle, and prep the uprights by sliding on the 90 degree pieces using the 10mm bolts with T-nuts, do not tighten them so they can be slid into place later. They are slid onto the sides of the frame where the middle will have 90 degree pieces on both sides while the outer pieces will only have the 90 degree pieces on the inner side, you will need six 90 degree pieces per upright.

5.3. Once the frame is prepped, grab a corresponding lower fan panel, and using help to hold the uprights use a screwdriver and 14mm screw to connect the panel to the uprights with the 90 degree pieces, taking extreme caution to not strip the threaded inserts in the panel. Take care to not fully tighten the screws at this time. After the first bottom piece is on, attach the second bottom piece. Ensure the panels are level to each other and if needed use a small shim (a spare T-nut can be used) by placing it under the needed panel on top of the middle support piece. Using the same process attach the top panels. Once all screws are in and panels attached the screws can be fully tightened.

5.4. Next step is to install the signage on top. Start with the sign with 2x supports, and prep it with the 10mm screws with T-nuts. Ensuring to leave the holes needed for connecting the second sign piece. Once the first sign panel is tightened down, prep and attach the second sign panel. The middle sign support requires spacers (oversized nut) to ensure the sign is aligned properly. While installing the second sign piece ensure the RGB cable is connected between the signs.

5.5. Install the kick plate on the front next, these use T-nuts and slide onto the front of the front of the supports. It may be required to use the included mallet to tap the legs to the left and right to align them properly and will square up the wall. The kick plates should not require much force to slide on and should only be hand done. The kick plates are not load bearing and should not be stood on. Once both kick plates are on, fully tighten the screws.

5.6. The power supplies should next be installed, this is easily done using the velcro straps on the back of the wall. The power supply closest to the power port on the top signage will have an extra cable to power the sign. Connect the included power supply cables to power the RGB controllers and fan controllers.

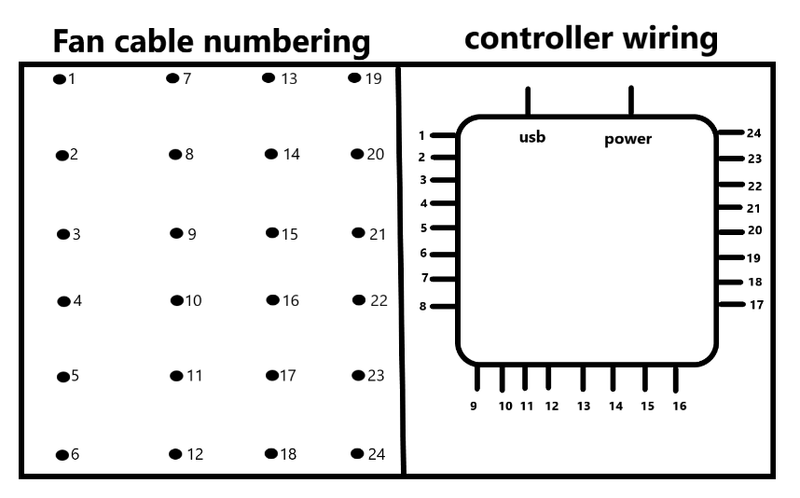

5.7. Installing the RGB controllers, looking at the back of the wall starting in the top left the wires are labeled 1-24 going from top to bottom, left to right. The RGB controllers have corresponding numbers on the case to the wires.

5.8. Once the wall is assembled connect the wall to a PC with the included USB cables, direct connections to the PC is best as hubs and extensions may cause signal degradation issues. Once connected to the computer there should be 9x controllers, one for the sign and 8x fan RGB controllers. The fan controllers will use a custom plugin that will make all 24 fans show up as one device, and the sign will appear as another custom single device. Going through one by one connect the controllers and in SignalRGB set their correct position in the app until the wall is fully lit up. Note that the top and bottom are rotated 180 degrees to each other so you will need to flip the top 4 controllers to make it look correct (there is a rotation slider in the app you can set to 180 to do this). Then align the sign on top and adjust the scale of everything to take up as much of the canvas as possible and try to center it.

6. Parts lists

The number in parenthesis is an estimate, some are exact and some include spares.

https://8020.net/3859.html -t-nut (50)

https://8020.net/3067.html -screw for 45 degree support (12)

https://8020.net/3382.html -t-nut for 45 degree support (12)

https://8020.net/3258.html -washer for 45 degree support (12)

https://8020.net/11-6314.html -14mm length screw (40)

https://8020.net/11-6310.html -10mm length screw (50)

https://8020.net/14059.html -90 degree pieces (30)

https://8020.net/2020-s.html - 6’ uprights, End Taps - 2 x 7067 end taps (6mm), Length - 72 Inches (x3)

https://8020.net/2020-s.html - 3’ feet, Length - 36 Inches (x3)

https://8020.net/2567.html - 45 degree support pieces (x3)

https://www.amazon.com/dp/B0BK3RZ4QL?th=1 M4x35mm .7 pitch screws 50ct (x16)

https://www.amazon.com/dp/B0B6HVS72Z - 200pcs 1/2" OD x 3/16” ID x 1/16”neoprene washers (x4)

https://www.amazon.com/gp/product/B0BN46CW6R -6mmx65mm for 6' uprights (12)

https://www.amazon.com/dp/B09NFGGVP5 - 2pc molex to 8 way fan speed controller (x12)

https://www.amazon.com/dp/B01N2RA59S - M4 x10mm threaded inserts 100pcs (x8)

https://www.amazon.com/Loctite-Epoxy-0-85-Fluid-Syringe-1395391/dp/B07PMLCHK7 loctite epoxy for signage and M6 threaded inserts

https://www.amazon.com/Liquid-Nails-4-Ounce-Projects-Adhesive/dp/B07G2R94TD LIquid nails for signage.

https://www.amazon.com/dp/B071R6H1KS - white opaque acrylic for the signage.

https://www.amazon.com/BTF-LIGHTING-Upgraded-Individually-Addressable-Non-Waterproof/dp/B07LG6J39V - LEDs for the signage (x2)

https://www.amazon.com/LM2596s-Converter-Step-down-Regulator-Stabilizer/dp/B07CVBG8CT - buck converter for sign controller

https://www.amazon.com/dp/B0CGD541J4 - #8 x 5/8" Wood Screws Phillips Truss Head

The custom RGB controllers are made using the following parts per controller (x8 minimum needed)

https://www.digikey.com/en/products/detail/sparkfun-electronics/DEV-20359/16688101 x1 teensy microcontroller

https://www.adafruit.com/product/3975 x3 adafruit level shifter

https://www.amazon.com/gp/product/B09XTN9N9S male or female as needed x1

https://www.amazon.com/gp/product/B09V9YYFD3 x3 (24 headers total)

https://www.dropbox.com/scl/fi/tfjef7xq414oqvc4jnfny/GERBER-Bequiet.zip?rlkey=w75i00so5yd18shjzxuv8bqi8&st=crvb3dw1&dl=0 - PCB GERBER file, can upload to JLCPCB and have more made. X1

https://www.amazon.com/gp/product/B07GJJXQ22 x1 USB cable

https://www.amazon.com/dp/B077CJV3Z9?ref=ppx_yo2ov_dt_b_product_details&th=1 - heat set inserts for the case

https://www.amazon.com/dp/B09NR8X2LV - assorted M3 screws for the case

https://www.newegg.com/be-quiet-pure-power-12-m-650w-650-w/p/1HU-004H-000S4 -PSUs for wall (x8)

https://www.amazon.com/dp/B09CT38FDJ - 24 pin PSU jumper (x2) Controller Firmware https://www.dropbox.com/scl/fo/n15mwsvvi3wgr0l1fdzc8/AOCZZvEtGO_gWVoaxYjrYBA?rlkey=94kgf8ooag6n90z7z01shiv92&st=jfuhnmhq&dl=0

Controller Case STL files for 3d printing

https://www.dropbox.com/scl/fi/qvg4r30xhyhatj9038ul0/Case-Bottom.stl?rlkey=x41olkuf07scxyl8ghv6kms5j&st=lvmc5slt&dl=0 - case bottom

SignalRGB plugins and components, feel free to reach out if you need help putting these in the right folder. These files go into the \Documents\WhirlwindFX folder and once there ensure the app is restarted.

Files for CNC machine for cutting -https://www.dropbox.com/scl/fi/qso5v8x0oe8qj6few1jz7/11-28-23-be-quiet-Acrylic-letters.dxf?rlkey=4mu9uvq81pbkbop2slbhx63yp&st=hvhyq7m2&dl=0 - Autocad files for CNC cutting of acrylic letters for the sign

-https://www.dropbox.com/scl/fi/e2ueps3rm05xpeo0n8oxd/11-28-23-be-quiet-Acrylic-letters.eps?rlkey=9yr1v1hyz5umbgoqtunc0h4nv&st=mo50su6a&dl=0 - Gimp file showing the cutouts of the acrylic letters to be efficient with the lettering

-https://www.dropbox.com/scl/fi/t5gvweer98gxnh5s2cr6v/11-28-23-be-quiet-ply-sign-panels.dxf?rlkey=26vyucipuwukwqykpgt47b3j5&st=lo65oh3x&dl=0 - Autocad file for CNC cutting the wood for the acrylic letters to sit in

-https://www.dropbox.com/scl/fi/1xkvakq6d0icuu3o3b6uu/11-28-23-be-quiet-ply-sign-panels.eps?rlkey=zjoyh8eis3c3va219hl3in1sr&st=hx8wqedd&dl=0 - GIMP file showing wood cutouts for the sign

-https://www.dropbox.com/scl/fi/6uylxq1icki1n7aksqxbs/11-30-23-be-quiet-fan-Panel-1-3.dxf?rlkey=48oqsuvkzd3vefx120z8r4sf0&st=lqam1wz7&dl=0 - AutoCAD file for CNC cutting of panels 1/3

-https://www.dropbox.com/scl/fi/2nto4nhi6to8scl2rv5u5/11-30-23-be-quiet-fan-Panel-1-3.eps?rlkey=npzo62v6iqtdc16xbyuu8hhjy&st=o9e6iqqd&dl=0 - GIMP file showing the cutouts for the 140mm fans for panels 1/3

-https://www.dropbox.com/scl/fi/b0oi84p5c3i2u42mxbu6z/11-30-23-be-quiet-fan-Panel-2-4.dxf?rlkey=f40ij79wvnzhi2q3bda9y3gyt&st=oyjoa3z0&dl=0 - AutoCAD file for CNC cutting of panels 2/4

-https://www.dropbox.com/scl/fi/9boz5bcys46oo8kanmllr/11-30-23-be-quiet-fan-Panel-2-4.eps?rlkey=n9p3o1yqaw7yhfekfythni4mw&st=55qwz1gx&dl=0 - GIMP file showing the cutouts for the 140mm fans for panels 2/4